Ever wondered about the amazing story behind your favorite kayak? Hobie kayaks have a tale that’s full of passion, innovation, and love for water sports.

Looking into where Hobie kayaks are made, you’ll find a worldwide network. It mixes American skill with global know-how. From California to places all over, Hobie leads in kayak making.

The place where Hobie kayaks are made is more than just a spot on a map. It shows years of top-notch engineering and a promise of quality. Whether you paddle for fun or seriously, knowing where your kayak comes from makes your journey even more special.

Key Takeaways

- Hobie kayaks have a rich manufacturing heritage spanning multiple global locations

- The brand combines innovative design with high-quality production techniques

- Manufacturing facilities ensure superior kayak performance and durability

- Hobie’s production process reflects a commitment to water sports excellence

- Global manufacturing network supports diverse kayaking needs

The Legacy Behind Hobie Kayaks: From Surfboards to Innovation

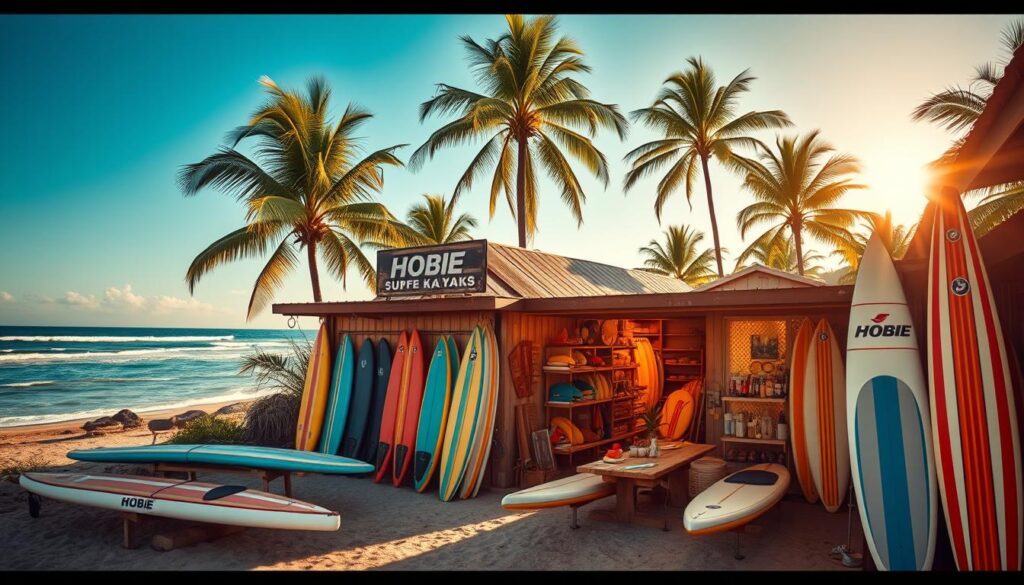

Hobie kayaks started with Hobie Alter, a passionate craftsman. He changed water sports forever. His small surfboard workshop in California grew into a legendary brand.

In the 1950s, Hobie Alter began making custom surfboards. His talent in materials and design made him stand out. By the 1960s, he had changed surfing with new manufacturing methods.

“Innovation is not about perfection, but constant improvement” – Hobie Alter

Switching to kayaks was a natural step for Hobie’s company. They used their knowledge of water and materials to make kayaks that were both useful and new.

- 1950s: Started with custom surfboard production

- 1960s: Pioneered new manufacturing techniques

- 1970s: Expanded into kayak design

- 1980s: Established global reputation for quality watercraft

Hobie’s focus on quality and innovation has never wavered. They keep improving, making kayaks that meet the changing needs of water sports fans. They stay true to the values of their founder.

Where Are Hobie Kayaks Made: Inside Their Global Manufacturing Network

Hobie kayak factories are found across the globe. They have a big network of places to make kayaks. This is to help kayak lovers everywhere.

Hobie’s kayak plants are in the best spots for making and sending out kayaks. Let’s look at how they make kayaks all over the world.

Primary Production Facilities and Their Locations

The company has key places to make kayaks in different areas:

- United States (Oceanside, California – main base)

- Asia (special places for making)

- European making centers

- Australian making sites

Quality Control Standards Across Manufacturing Sites

Hobie checks every kayak very carefully. They make sure each kayak is the best:

- They pick the best materials.

- They test each kayak in detail.

- They check every kayak carefully.

“Our goal is to make the best kayaks,” – Hobie Manufacturing Team

Distribution Centers and Assembly Points

| Region | Primary Distribution Center | Key Markets |

|---|---|---|

| North America | Oceanside, California | United States, Canada |

| Europe | Netherlands Hub | European Union Countries |

| Asia-Pacific | Singapore Logistics Center | Australia, Southeast Asia |

Every place helps send kayaks fast and helps local fans.

Exploring Hobie’s Oceanside California Headquarters

The Hobie kayaks made in USA headquarters is in the heart of Southern California. It shows the brand’s innovative spirit and American manufacturing. Located in Oceanside, it’s more than a place. It’s the heart of a legendary water sports company.

Visiting Hobie’s headquarters is a journey into design and manufacturing excellence. It’s a place where research, design, quality control, and customer support come together:

- Research and development center

- Primary design hub for new kayak models

- Quality control and testing facility

- Customer support and technical resource center

The Oceanside location is more than a manufacturing site. It’s the strategic center for Hobie kayaks made in USA. Visitors can see the brand’s dedication to marine innovation everywhere.

“Our Oceanside headquarters represents the soul of Hobie – where passion for water sports meets cutting-edge design,” says a company representative.

The Oceanside location has many advantages:

| Advantage | Impact |

|---|---|

| Proximity to Pacific Ocean | Direct testing environment for kayak prototypes |

| California Innovation Culture | Attracts top engineering and design talent |

| Manufacturing Ecosystem | Access to advanced production technologies |

Hobie keeps its headquarters in Oceanside to honor its roots. It also pushes the limits of kayak design and manufacturing. The facility shows the brand’s dedication to American craftsmanship and marine innovation.

The Manufacturing Process: From Design to Delivery

Explore the detailed world of Hobie kayak production sites. Here, innovation and precision come together. The journey from design to final product is carefully planned. It ensures each kayak is of the highest quality and performance.

Raw Materials and Component Sourcing

Hobie starts with the best raw materials. The kayak production sites focus on durable and high-performance components. Key materials include:

- Marine-grade polyethylene

- Lightweight aluminum frames

- Advanced composite materials

- UV-resistant plastics

Production Techniques and Technology

At the core of Hobie kayak production sites is advanced technology. Precision molding and computer-aided design (CAD) ensure each kayak is made to exact specifications.

| Manufacturing Technique | Key Benefit |

|---|---|

| Rotational Molding | Seamless, durable kayak construction |

| CNC Machining | Precise component fabrication |

| 3D Printing Prototyping | Rapid design iteration |

Final Assembly and Testing Procedures

Each Hobie kayak is tested thoroughly to ensure top performance. The final assembly includes:

- Comprehensive quality inspection

- Water-tight seal verification

- Functional component testing

- Performance stress testing

“Every kayak that leaves our production sites is a testament to our commitment to quality and innovation.” – Hobie Kayak Engineering Team

Hobie kayak production sites are the best in kayak design and construction. They use top materials and advanced techniques.

Made in USA: Hobie’s American Manufacturing Heritage

Exploring Hobie kayaks made in USA reveals a deep American manufacturing legacy. The company stays true to domestic production. This commitment creates top-notch watercraft that showcase American craftsmanship at its finest.

Hobie kayaks made in the USA are known for their quality and precision. Their production process offers several benefits of American-based manufacturing:

- Direct oversight of manufacturing processes

- Rapid prototype development

- Stringent quality control standards

- Support for local manufacturing jobs

“We believe in American manufacturing and the skills of our local workforce,” says a Hobie company representative.

The dedication to making hobie kayaks in the USA goes beyond just production. It’s about upholding high engineering and design standards. These standards have made the brand a leader for decades.

| Manufacturing Location | Product Lines | Key Advantages |

|---|---|---|

| Oceanside, California | Mirage Kayaks | Advanced R&D, Direct Innovation |

| Southern California | Specialty Watercraft | Precision Manufacturing |

Your love for quality watercraft meets American ingenuity with Hobie’s approach. By keeping production in the USA, they ensure each kayak is top-notch in performance and reliability.

International Production Facilities: A Global Footprint

Hobie Kayaks has set up factories on several continents. This global network meets the needs of markets all over. It makes sure high-quality kayaks get to customers everywhere.

European Manufacturing Centers

In Europe, Hobie has special factories for kayaking fans. These places focus on making kayaks with precision and designs for European waters.

- Streamlined production processes

- Local market-specific design adaptations

- High-quality European manufacturing standards

Asian Production Facilities

Hobie kayaks made in China are a big part of their global plan. The Asian factories use the latest tech and ways to make things cheaper. This helps them send kayaks all over the world.

“Our commitment to quality transcends geographical boundaries” – Hobie Kayaks Leadership

Australian Operations

The Australian factory is key for the Oceania area. It makes kayaks that fit the Australian coast perfectly.

| Region | Key Manufacturing Focus |

|---|---|

| China | Cost-effective production |

| Europe | Precision engineering |

| Australia | Regional design adaptation |

Hobie Kayaks keeps factories on different continents. This makes sure kayaks are available everywhere. It also means they can be made to fit each region’s needs, keeping quality high.

Sustainability Practices in Hobie’s Manufacturing

Hobie kayak production facilities have changed the game for environmental responsibility in water sports. The company is dedicated to sustainable practices. It sets a new standard for eco-friendly kayak design.

When you paddle with Hobie, you’re choosing an eco-friendly option. The company has made big strides in reducing its carbon footprint. Here are some of their key strategies:

- Recycling advanced composite materials

- Minimizing waste in hobie kayak production facilities

- Utilizing renewable energy sources in manufacturing

- Developing eco-friendly resin and material alternatives

“Sustainability isn’t just a goal—it’s our responsibility to the planet and future paddlers.” – Hobie Kayak Design Team

Hobie’s commitment to the environment is seen in their material choices and production methods. They use lightweight, durable materials. These materials are good for the planet and don’t sacrifice performance.

| Sustainability Metric | Current Performance | Environmental Impact |

|---|---|---|

| Recycled Material Usage | 45% | Reduced Carbon Emissions |

| Energy Efficiency | 62% Renewable | Lower Manufacturing Footprint |

| Waste Reduction | 35% Less Waste | Minimal Environmental Strain |

Hobie keeps setting new standards in sustainable kayak making. This ensures your love for water adventures also cares for the environment.

Future Manufacturing Plans and Expansion

Hobie kayak manufacturing is getting a boost with new growth plans. The company aims to stay ahead in the kayak world. It’s planning to grow and use the latest production methods.

Hobie has big plans for its manufacturing network. It wants to improve production and use new technology.

Upcoming Facility Developments

The company has several key plans for growth:

- Expanding the Oceanside, California headquarters to increase production capacity

- Developing new manufacturing spaces to streamline kayak production

- Investing in state-of-the-art production facilities

Technology Integration Goals

Hobie’s vision for the future includes big tech upgrades:

| Technology Focus Area | Planned Implementation |

|---|---|

| Advanced Materials Research | Developing lighter, more durable kayak materials |

| Automated Production Systems | Implementing precision manufacturing technologies |

| Digital Design Integration | Enhancing 3D modeling and prototype development |

“Our commitment is to continually push the boundaries of kayak manufacturing innovation,” says a senior Hobie executive.

Hobie is committed to staying a top kayak maker. It’s focused on using new tech and improving production.

Conclusion

Exploring where Hobie kayaks are made takes you on a journey of innovation across continents. Starting in Oceanside, California, Hobie has grown to have production facilities all over the world. They are known for making top-notch watercraft that stand up to quality and performance tests.

Looking into Hobie’s manufacturing shows their dedication to precision and global strategies. The story of where Hobie kayaks are made is one of tech progress, green practices, and understanding what water sports fans want. With production sites around the globe, Hobie makes kayaks that go beyond what you expect in terms of performance and lasting quality.

Hobie keeps improving kayak design and making by using international manufacturing. They mix American creativity with worldwide production skills, making sure every kayak is up to their high standards. Whether you paddle for fun or seriously, you can count on the quality of every Hobie kayak.

Looking ahead, Hobie’s focus on innovation, sustainability, and quality water sports gear remains strong. Their global production shows their dedication to making kayaks that spark adventure and exploration. Hobie’s commitment to excellence is clear in every kayak they make.